Voltar à visão geral

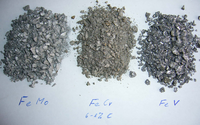

Comminution of ferro alloys

Ferro alloys consist of iron endowed with vanadium, titan, chrome, niobium, silicon or manganese, only to name the most common ones. Often contain the alloys - besides the name given elements - additional elements. Therefore, different and varying compositions always result in an analysis of the contents. In the case of the ferro alloys the wet-chemical pulping is necessary and only possible, if the material is available in a powder form.

Comminution with FRITSCH Mills

We recommend for this particular application as a first step the preparation with the Jaw Crusher PULVERISETTE 1, model II classic line, equipped with hardmetal tungsten carbide crushing jaws. Without problems most ferro alloys can immediately be crushed down to the maximum possible fineness. The sample is added into the jaw crusher not too fast. Ferrochromium is to be considered as a borderline application and can only be processed with a higher carbon content.

Milling with the PULVERISETTE 9

In a second step, the with the jaw crusher produced material is to be crushed finely. Only the Laboratory Vibrating Cup Mill should be considered for this. We recommend the Vibrating Cup Mill PULVERISETTE 9 equipped with a hardmetal tungsten carbide grinding set. With extreme materials the fine share is sieved off and comminuted again. The fineness obtained with this procedure is a good compromise between the running time of the vibrating cup mill and the use of the grinding set. The abrasion from the steel set corresponds in its chemical composition with the main components of the sample and therefore can be tolerated.

For the ensuing acid hydrolysis, the obtained fineness is completely sufficient. Various matched to the material acid mixtures are used for this. With suitable measurement methods like the ICP or the AAS the alloy components are determined.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Voltar à visão geral