Voltar à visão geral

Homogenization and Characterization of Cannabidiol (CBD) Isolates

Solid isolates of CBD may be created as a non-homogenous “cake” of material, or as a mixture of loosely associated granules comprising a wide particle size distribution. Creating material suitable for consumption or subsequent formulation in other products typically requires particle size reduction and/or homogenization. Confirmation of particle size distribution of a given sample may be achieved via traditional sieving methods, or by using a particle size analyser.

Primary considerations when selecting a milling system for CBD homogenization include:

•Batch size (throughput requirement kg/batch/day)

•Minimizing losses (physical and/or chemical)

•Desired final particle size range

•Ease of cleaning to prevent batch cross-contamination

Homogenization – small-scale

Small-scale homogenization of CBD isolate may be achieved by low energy ball milling, or by automated mortar and pestle. Larger batches may be processed in a continuous manner by using the FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 classic line, with Cyclone separator

Fig. 1: Inside of a Variable Speed Rotor Mill PULVERISETTE 14 classic line, showing fixed collection vessel, rotor and sieve ring. The high-performance Cyclone separator made of stainless steel is shown on the right.

Configured as a continuous milling system, the PULVERISETTE 14 classic line with Cyclone allows continuous feeding of material, and active removal of material from the rotor area – typically within a fraction of a second. Because the homogenization occurs so quickly and the material is actively removed, there is no time for frictional temperature increase to occur that could cause chemical degradation. Product contact surfaces are stainless steel, or food-grade plastic vacuum hose for the Cyclone, and can all be cleaned thoroughly between batches to reduce the likelihood of cross-contamination. Variable speed motor and range of sieve rings, provides control of particle size output. Used together with collection vessel, the PULVERISETTE 14 classic line and Cyclone separator allow continuous feeding and homogenization of CBD material into the low micron range (consistency of talcum powder).

Homogenization – large scale

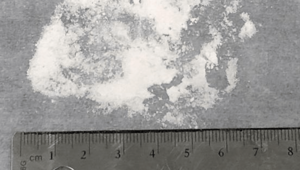

Production-scale homogenization of CBD isolate into uniform powder can be achieved with the FRITSCH Universal Cutting Mill PULVERISETTE 19. Already considered the premier, precision milling solution for preparation of cannabis biomass for extractions, or pre-roll products, the cutting mill may be configured as a large-scale homogenizer to allow continuous processing of large batches of isolate material.

Fig. 2: Left side shows the PULVERISETTE 19 cutting mill system, shown with high-performance Cyclone separator mounted to 60 L collection vessel.

Right side shows image CBD isolate homogenized into the low-mid micron range using the Universal Cutting Mill PULVERISETTE 19.

Suggested system settings:

• Between 2000 – 3000 rpm

• Rotor with notched edges and fixed knives

• Gap setting between cutting rotor & fixed knives: 1 – 2 mm

• Sieve cassette: 1, 2, or 4 mm (depending on nature of sample material & desired fineness)

• High-performance Cyclone separator made of stainless steel

Particle size analysis

Characterizing the particle size distribution of a sample may be performed for the following reasons:

• To confirm that a milling system has achieved particles within an accepted range

• In Quality Control: As a criterion for release into the manufacturing process (raw material testing) or for product sale

• In R&D: To study the efficacy of a compound based on its particle size, and/or on the perceived quality of a formulated product

Particle size analysis by traditional sieving methods involves passing the material through a series of sieve pans with progressively smaller openings, and calculating the weight of material that is retained in each pan. Data obtained by using this method is limited by the number of different sieves that are used, and can be confounded if and when particles stick to the metal surfaces.

Particle Sizing with FRITSCH instruments

Laser particle size analysers with reverse Fourier optical system, pioneered and patented by FRITSCH over 35 years ago, have become a worldwide standard across a wide range of industries, for precise size characterization of materials down into the low nanometer range. The Laser Particle Sizer ANALYSETTE 22 has been used successfully to characterize CBD isolates, using either a wet or dry dispersion method.

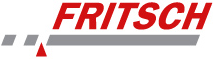

Fig. 3: The ANALYSETTE 22 was used to measure CBD isolate before & after homogenization. Starting CBD sample (orange) contained a mixture of loose granules with a wide particle size distribution. Material homogenized using the Variable Speed Rotor Mill PULVERISETTE 14 classic line (purple) resulted in a particle size consistency similar to talcum powder.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Voltar à visão geral