Voltar à visão geral

InSitu Acquisition of Grinding Parameters

FRITSCH's Planetary Mono Mill PULVERISETTE 6 classic line

In the laboratory sector planetary ball mills are usually utilised to reduce the size of a broad range of samples in batches at high energy. The milling principle of planetary ball mills is based on the movement of grinding bowls securely fastened to the mill whereby the bowls are filled with grinding elements and the sample to be ground. Specific movements of the grinding elements are actuated due to the complex sequences of movements of these grinding bowls. These movements are exploited to reduce the size of the sample. Whenever a new planetary ball mill is being constructed or an older one upgraded, efficient grinding, i.e., the optimised movement of the grinding elements, will always be one of the designer's primary objectives.

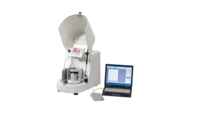

With the Planetary Mono Mill PULVERISETTE 6 classic line FRITSCH GmbH introduced another in its series of planetary ball mills. This revolutionary new instrument was first presented to experts at the Achema '97 trade fair and is now firmly established. The main features of interest during the development of the planetary mono mill were maximum grinding results and minimum footprint.

With the planetary ball mills under consideration, the aim is always to create a grinding element regime in the grinding vessel which is similar to the well-known cataract regime of conventional ball mills. The grinding balls are carried up the inner wall of the bowl and, under certain conditions (forces exerted on the grinding element), are propelled off the wall. The grinding balls then fly across the bowl, colliding with the opposite wall of the bowl and crushing the sample.

With earlier planetary ball mill designs, the kinematics of the mills were always perfected to ensure an optimal launching point for the grinding elements as learned from the conventional ball mills.

The grinding drum of a ball mill functions in earth's gravity field, whereas the movement of a ball in the planetary ball mill is due to the superposition of various centrifugal and coriolis forces. Naturally, a simple extension of these bases for calculation therefore yields no more than a rough approximation. Recent studies of the kinematics of planetary ball mills disclose that the most important parameter in terms of the grinding is not one specific launching point; it is the changeable direction of the collision of the grinding element with the wall of the bowl.

Of course, the launching point is not unimportant insofar as grinding element kinematics is concerned, however it is no longer assumed to be an unchangeable, fixed parameter. Instead it changes as the path of the grinding elements across the bowl changes.

The aim is always to design the parameters of the planetary ball mill such that flight path of the grinding elements normally ends at the inner wall of the bowl.

Above and beyond this, the PULVERISETTE 6 is the first real planetary ball mill with just one grinding station. Earlier mills of this type always featured an even number of grinding stations (usually 2 or 4). Mill symmetry therefore compensated for imbalances which developed. Here, adjustable imbalance compensation is integrated for the first time. It is thus possible to handle greatly differing masses (different grinding bowls, balls and sample amounts) without additional compensating masses.

In Situ Acquisition of Grinding Parameters while Preparing Samples: GTM System

To date, the physical and chemical processes which occur while powders are being ground are largely unknown. Until now, whenever data regarding the process was required, intermediate studies have been required in order to describe the progress of size reduction, mixing, activation, amorphisation or phase transformation processes. These studies were conducted outside the grinding bowl on samples whose condition was seldom identical with the conditions of the powder during the grinding process. This gave rise to the challenge of developing a measurement process which would make it possible to obtain meaningful process data during grinding.

At the Achema '97 Fritsch GmbH premiered and in the meantime established the GTM system and it enables the user to measure and assess the temperature and the gas pressure in the grinding bowl simultaneously during the grinding process. This system was developed in cooperation with the Fraunhofer Institute for Applied Material Research in Dresden. The system is utilised for process imaging during mechanical alloying as well as to describe reaction sequences during high energy grinding in planetary ball mills. In addition, it can be applied to optimise grinding processes (e.g. for samples which are only to be subjected to limited effects of heat). Aside from this, the system could also be employed, for example, to control processes instead of just imaging them.

The system offers the user the opportunity to acquire and evaluate temperature and gas pressure simultaneously but separately from each other. Measuring the temperature of the grinding bowl enables an integral statement as to the process parameter temperature which factors into the effect of all friction, impact and transformation processes but not rapidly transpiring calorific effects. Very rapid or slight temperature changes are acquired by continuous and highly sensitive measurement of the gas pressure in the grinding bowl. The gas pressure measured contains information about the increase in temperature due to the warming of the grinding bowl but it also describes the interaction of the gas with the surfaces created during grinding (adsorption and desorption of gases) and takes into account the entire volume of powder (decomposition and release of gases during grinding).

An electronic system converts the measured values into digital signals and permits a very broad range of adaptations to the special problems of our clients. In addition, the measured values are then transmitted by radio to the receiver unit (serially connected to the PC) for up to 80 hours (various transmission modes). Windows software handles the visualisation, recording and evaluation of the data.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Voltar à visão geral