Voltar à visão geral

The significance of drive power for the efficiency of the Variable Speed Rotor Mill

1. Introduction

The aim of all comminution is to achieve a certain fineness (by fineness, we mean a particle size distribution Qr(x) or a mean grain size x. The fineness is a directly measurable quality requirement to be met by the product. It has a decisive influence on the properties of the product, but is not the only influencing quantity).

During comminution, particles of a starting material are broken to form many smaller particles.

Breakage occurs as elastic stress reaches a critical level within the particle. In addition, incipient cracks, which serve as the cause of sufficiently high local stresses, must also be present before breaks can occur at all. In rotor speed mills, rotating cutting tools impact at high speed against the particles. At impact, the kinetic energy of the impact tools gives rise to a deformation in the contact area, which ultimately leads to the break.

The comminution effect is heightened by the shear forces between the rotor and the sieve rings used. Because of the high rotational speeds, high throughputs are achieved. The duration period of the sample in the grinding chamber is short in order to ensure gentle processing of the samples.

The comminuted sample is retained in a collecting vessel or vacuumed out for bulk collection or further processing.

There is a very extensive range of accessories for such mills. Thus, conversion from batchwise grinding to continuous grinding of large quantities, for example, can be accomplished in a short period of time.

2. The breaking process

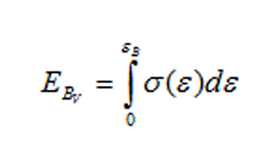

An important factor for comminution is the required energy input in the form of mechanical work which must be expended until the break occurs. The elastic stress field produced supplies the energy for initiation and propagation of the break. The energy per unit volume is given by with

EBv energy expenditure up to breakage

σ stress

ε strain

If the stress σ is plotted against the deformation ε, three different types of material behaviour for solids result:

Linear elastic

Strain and stress are proportional to each other and follow the same path during loading and unloading. The proportionality factor is called the modulus of elasticity, with σ stress ε strain.

For brittle materials, the modulus of elasticity is large, and almost no deformation occurs prior to breakage. The breaking work per unit volume is small, whilst the necessary breaking stress is great. Comminution requires only a low expenditure of energy.

For rubber-like elastic materials, the modulus of elasticity is low, and even low stresses effect fairly large deformations. The breaking work per unit volume is large, whilst the breaking stress is relatively low. Such materials are more difficult to comminute. The volumes placed under stress should be small so that the energy can be concentrated in a smaller region. For comminution, small tools, i.e. sharp cutting edges, should if possible be used.

Elastoplastic

With many materials, when a certain limit is exceeded, an irreversible deformation, that is to say plastic flow, occurs prior to breakage. Above this yield point, a very small loading increase effects large, irreversible deformations. Unloading prior to occurrence of a break can result in a small elastic strain decrease.

The breaking work per unit volume is large, whilst the elastically stored energy is low. The breaking process is dependent neither on the loading speed nor on the duration, that is to say it is independent of time. The comminution requires only a low expenditure of energy.

Viscoelastic

The comminution process is time-dependent; the material creeps and relaxes, e.g. thermoplastics. The specific expenditure of work up to breakage is large, whilst, with time, the stored elastic internal energy is converted to heat. Very short loading times (< relaxation time) lead to embrittlement, i.e. lower deformation - higher breaking stress - larger elastic energy component - lower specific breaking work. The same effect can be achieved by temperature reduction (e.g. cold comminution of rubber, unvulcanised rubber, etc.).

3. Breaking behaviour

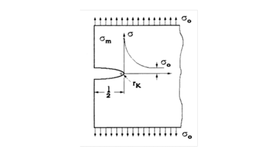

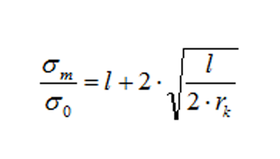

The following relation applies for a simple model (uniaxial tension, linear elastic behaviour, elliptical incipient crack) with

l length of the entire incipient crack

rk notch radius

σm maximum stress at the crack tip

σ0 homogeneous stress in the sample

The stress concentration at the crack tip is higher, and the incipient crack thus more effective for break initiation

a) the longer the incipient crack and

b) the smaller its notch radius.

This leads to the following important points for technical comminution:

1. During comminution, the incipient cracks are used in accordance with their effectiveness. The further the grinding process has progressed, the lower the number of effective incipient cracks still present.

2. The smaller the particles become, the smaller (shorter) the incipient cracks still present.

3. Depending on the material, the micro plasticity (ductile zone at the crack tip) determines the lower limit of fineness which can be produced by brittle comminution.

4. Crack propagation

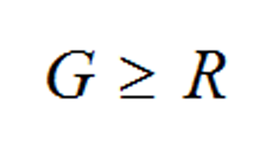

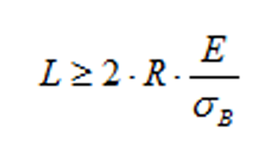

Crack propagation depends on the energy supplied. A crack can be propagated only if the energy required per unit area of the break surface can be provided by release of the elastic energy stored in the immediate vicinity of the crack tip. The energy requirement per unit area of the break surface is referred to as crack resistance R. The rate of release of energy G is defined as the energy released per element of area.

From the differential energy condition - (the energy consumed by crack propagation must at least be replenished if the crack is not to remain stationary), and the integral energy condition

(the elastic energy stored in the sample must suffice or be replenished in order that the break can pass completely through the sample), the following applies for fine comminution:

1. "Soft" materials should be loaded in the smallest possible volumes, i.e. with high local energy densities (e.g. with cutting edges).

2. If the particles to be comminuted are so small that the required volume is not sufficient for storage of the energy supply, the entire energy for each individual dividing process must be provided from outside. Small grinding tools are necessary for this. Since not every loading is sufficiently large for a break, loading must be applied very frequently.

5. The Variable Speed Rotor Mill

The FRITSCH Variable-Speed Rotor Mill classic line comminutes soft to medium-hard material displaying linear-elastic or elasto-plastic material behaviour. After embrittlement even viscoelastic material can be comminuted. Due to brief duration times of the sample in the grinding chamber even temperature sensitive material can be comminuted.

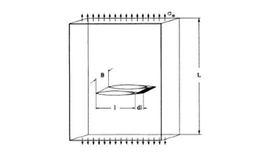

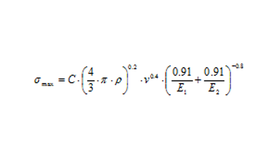

According to the Harz-Huber theory, the following equation results for a particle impacting against a surface with

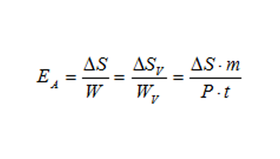

The rotor peripheral speed v is the parameter which exerts the decisive influence on the comminution result. The material density ρ and the moduli of elasticity of the tools and particles are constant. The comminution result is better, the higher the rotational speed of the rotor. Economical comminution is not possible below 60 m/s. The energy utilisation is defined as the increase in the specific surface area per unit of comminution work expended with

P motor power

W comminution work

m mass of material to be ground

t grinding duration

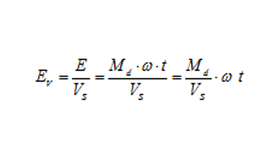

The comminution result for peripheral speeds < 60 m/s is very poor due to the low energy utilisation, because, for a constant power P of the mill, the grinding duration t is high and the mass m of material to be ground inserted per unit time is small. In addition, the specific energy (the energy expended per unit volume of solid material comminuted) is very small:

Md motor torque

Vs comminuted volume of solid material

ϖ angular speed

t time

Both the loading intensity, which is dependent on the torque Md of the motor, and the frequency of loading, which is dependent on the angular speed of the rotor, exert a great influence on the comminution result.

Loading intensity

The total torque of the mill is influenced by the rotor geometry. A large rotor is unfavourable because it reduces the torque of the mill. A rotor of smaller diameter favours the comminution result. In order to attained high impact speeds, it is not sufficient to simply to increase the rotor diameter while keeping the same motor. The associated torque reduction would lead to poor energy balances. In the FRITSCH Variable-Speed Rotor Mill PULVERISETTE 14 classic line, the comminution result was optimised by means of a favourable rotor geometry.

Frequency of loading

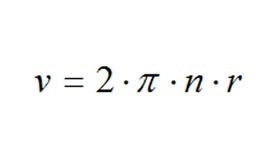

The frequency of loading is likewise very high with the FRITSCH PULVERISETTE 14 classic line. With the equation for the peripheral speed with n rotational and speed r rotor radius

a peripheral speed of 92 m/s is obtained from the rotational speed of the drive motor (n = 20,000 rpm) and the radius of the rotor used. The technical information on rotor speed mills often gives the idling speed. The equation above, however, always presupposes that there is material in the mill.

The important factor is to what extent the rotational speed of the rotor also remains constant after material is added. It is thus inappropriate to give the idling speed as it does not have any bearing at all on the comminution effect to be expected: In many mills, a universal motor is used for achieving high rotational speeds.

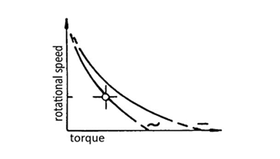

The disadvantage of such series-wound motors is the pronounced dependence of rotational speed on load torque, and the high carbon abrasion.

When a universal motor is used, a reduction in speed from, for example, 18,000 rpm at idle to 12,000 rpm under load can be expected. The peripheral speed will drop from 90 m/s to approx. 60 m/s. The comminution is uneconomical.

If the user relies on the rotational speed given, and also assumes this rotational speed under full load, all previously calculated parameters will be wrong. The comminution result will be unreliable.

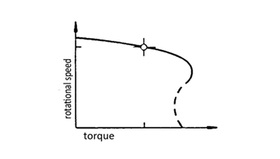

An important design feature of the FRITSCH PULVERISETTE 14 classic line is thus constancy of rotational speed under load. The Variable-Speed Rotor Mill is driven by a three-phase a.c. motor. A frequency converter permits an unrestricted choice of rotational speed between 6,000 and 20,000 rpm.

Use of a frequency converter also permits higher rotational speeds and adaptation of further parameters to the material to be ground. Thus, for example, the voltage torque Rotational speed – torque characteristic for three phase A.C. motor can be increased at low rotational speeds in order that sensitive samples can be comminuted at a low frequency but with the full torque. A microprocessor also keeps the speed constant under load. The speeds given agree with the actual speeds.

Use of the FRITSCH PULVERISETTE 14 classic line makes the comminution effect predictable. The user can be sure that the energy balance expected will be realised in full. Comminution will be reliable and reproducible.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Voltar à visão geral