Voltar à visão geral

Grinding teas – herbal tea, black tea or green tea

Up until now many users achieved very good, dependable analyses results in the heavy metal analysis of plants with rotor mills. On the one hand the demands and requirements in regards to exactness and reproducibility of the analyses results are rising and on the other hand the critical values for the contents of heavy metals are being further lowered. Today, newer analysis procedures like for example the ICP-MS allow the proof of trace elements up into the ppt-range. These instruments often operate with smaller net weights for the analysis. Therefore inevitably the requirements in regards to quality and homogeneity of the samples rises i.e. the samples have to be ground finer and finer.

Working principle of the Variable Speed Rotor Mill

Rotor mills distinguish themselves with a rotor with high rotational speeds. A sieve defines the fineness of the sample. Plants, especially their stems contain long fibred ligneous parts. The high rotational speed of the rotor causes an aligned air current. In this current though elongated parts are aligned in a manner so they can pass the sieve. An extreme example in regards to these material characteristics is described in the report Purple Moor-Grass. These characteristics limit the achievable end fineness.

Milling of green tea

In order to meet the new requirements of sample preparation we followed the request of a customer in grinding tea clearly finer, available tea was comminuted in the Planetary Micro Mill PULVERISETTE 7 premium line. The grinding set consisted of zirconium oxide grinding bowls with 15 mm diameter grinding balls.

Experience has shown positive results when zirconium oxide was used as the grinding material for the preparation of plant samples and also the chemical contents of zirconium oxide does not alter the analysis results.

Test with the PULVERISETTE 7 premium line

Comminution of green and black tea

Test with the Variable Speed Rotor Mill PULVERISETTE 14 classic line

In order to gather the quantifiable difference between these two mill types, the green tea was comminuted parallel to the above test with the Variable Speed Rotor Mill PULVERISETTE 14 classic line using a 0.08 mm sieve. With rotor, respectively centrifugal mills, a sieve defines the final fineness. Hence a reference point for the particle size distribution for the sample prepared in this manner exists. Optically both samples look very similar.

Determining the particle size distribution

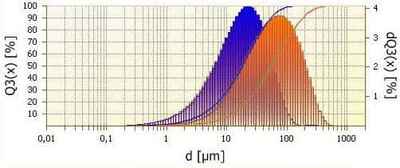

The determination of the particle size distribution with the FRITSCH Laser Particle Sizer ANALYSETTE 22 clearly shows a different picture:

All samples were measured in water. Both distributions are secured with three measurements in chronological order. There are no drifts of the measuring values over time. Tea can therefore be measured with those dispersion conditions.

Blue Curve

Green tea comminuted 3 minutes with the Planetary Micromill PULVERISETTE 7 premium line using zirconium oxide grinding bowls and grinding balls with 15 mm diameter

d10 = 3.9 µm d50 = 17.8 µm d90 = 53.8 µm

Orange Curve

Green tea comminuted with the Variable Speed Rotor Mill PULVERISETTE 14 using a 0.08 mm sieve

d10 = 12.2 µm d50 = 56.5 µm d90 = 184.4 µm

Despite using a 0.08 mm sieve in the Variable Speed Rotor Mill, are only 63 % < 80 µm, only 86 % < 160 µm – double the mesh width of the sieves - and 99.6 % < 400 µm – fivefold the mesh width of the sieves.

The reason for this is very simple!

A sieving is a two dimensional observation of the particle size. Oblong particles directed by the air current pass the sieve. But we always associate with a particle size a sphere – this is wrong. The Laser Particle Sizer regards by avoiding laminar flows in the measuring cell and a statically secured amount of measuring values, all three dimensions. Detailed information about these topics are contained in the report Molinia.

In conclusion: With planetary mills plant samples like different kinds of tea can clearly be ground finer than with a Variable Speed Rotor Mill.

-

Download the FRITSCH-report as PDF-file

-

Detailed grinding reports

Voltar à visão geral