Voltar à visão geral

Rock, Paper, Scissors: Ways that Milling and Sample Prep Affect Our Everyday Lives

Milling materials to reduce particle size ensures both our safety and the safety of our environment.

We often do not consider how the products we rely on every day are created or tested. Milling to reduce the particle size of a given material is one such example. The effect of milling is evident in products that allow us to communicate, enable our transportation, provide sustenance and healthcare, and much more. LCGC recently sat down with Barry Schubmehl, applications consultant at FRITSCH Milling and Sizing, to discuss how milling systems are involved in creating the products we use on a daily basis.

Why are various materials milled to reduce particle size?

Primarily, materials are milled to ensure either our safety or the safety of our environment, as well as to enhance the performance of a given product. Many of the analytical methods that may be used for a particular material require that whole material be reduced in size before testing takes place. Examples include testing for chemicals that could be toxic to us or for active ingredients in medicines that help us. For other products, particle size, consistency, and even shape can influence how the material performs, for example, in batteries that are used in our devices.

What types of common products involve a milling system for creation or testing?

These products could be numerous physical items that we come in contact with or that eventually need to be disposed of. Examples include foods that we consume every day; our clothing; various materials that we touch on planes, trains, and automobiles; materials used to make cell phones; materials in children’s toys; materials that are used to build our homes and offices; and so on. Despite my involvement in various scientific endeavors for nearly three decades, I am still blown away to learn how all of these everyday products that we use and take for granted are created and made safe through the milling process.

What does the children’s game “Rock, Paper, Scissors” have to do with the science of milling and sample preparation

When we share some of these principles at scientific conferences, we are often asked for recommendations on which milling methods to use. It occurred to us that there was insightful information in the rock, paper, scissors game that we grew up with. For example, to reduce the particle size of a plant-based sample such as paper, scissors would be used. To break apart a rock, paper would not do the trick and a hammer would be used.

What are some examples of these different types of milling technologies?

Soft or fibrous materials such as many foods, polymers, and textiles are efficiently processed using mills with some type of sharp blade to provide a cutting or slicing mechanism. Harder materials like various minerals, metals, ceramics, glass, and so forth are efficiently reduced in size by either direct impact forces (e.g., a ball or a hammering action) or through frictional or compression forces (e.g., a mortar and pestle).

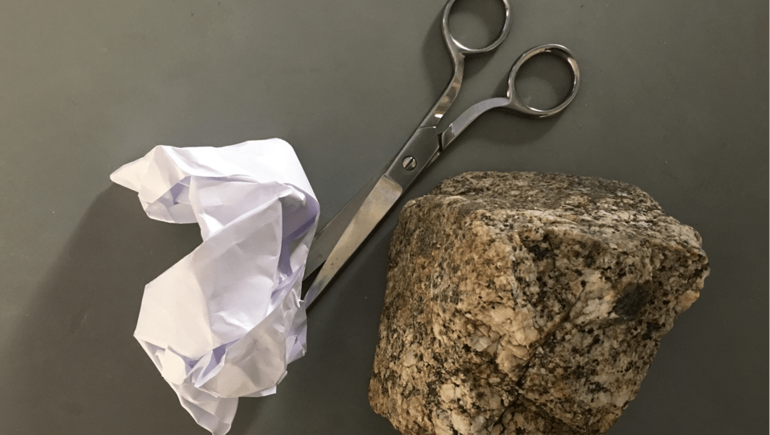

Some mills combine several of these different physical mechanisms. My favorite example is the planetary ball mill, which provides energy levels equivalent to 95 times the force of gravity. The planetary ball mill can be used to create nanoparticles or entirely new compounds.

With all of these options, how do you choose the right system?

It is important to understand both the physical and chemical properties of the material to be milled. We also need a good understanding of why the material is going to be milled as well as application-specific parameters such as sample volume, number of samples per day, and the desired final particle size range needed for the analysis.

Are there any risks or concerns if the wrong type of mill is used?

Yes, absolutely. When an inappropriate milling system is used, perhaps the biggest risk is that it could alter the physical or chemical characteristics of the sample. This results in bad data or data that are not representative of the whole material. If a mill alters the chemical profile of a sample (e.g., as the result of an uncontrolled temperature increase), there could be dangerous consequences, for example, in testing to confirm that food does not contain a pesticide or that a medicine has the appropriate concentration of an active ingredient. If a mill is causing some of those compounds to disappear, results obtained could be erroneous and potentially create a bad situation.

With that said, what are some of the most challenging milling applications?

Any samples that contain mixed materials with different physical characteristics could pose a challenge for milling; each subcomponent of a sample may require a different physical mechanism to reduce the size. A cell phone is a great example because it contains different types of materials that are combined in one little package. Aside from those occasional challenges, we tend to recall the more interesting and memorable samples that we have come across. These include a wide variety of items such as bones, dried crickets, dog treats, or any number of different materials combined in new ways to create novel substances. Such substances may even allow us to meet the rigors of travel in outer space.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

-

Sources

Original application report as it appeared on the LC GC website: Rock, Paper, Scissors Cool Ways Milling and Sample Prep Affect our Everyday Lives

Voltar à visão geral