Outros Jaw Crushers

OUTROS GRUPOS DE PRODUTO

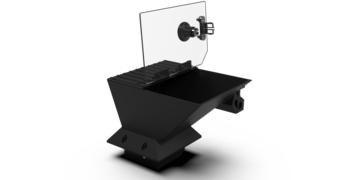

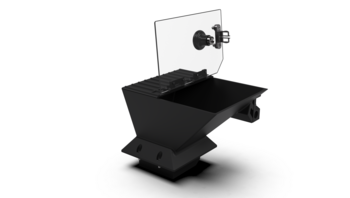

Jaw Crusher - Model II

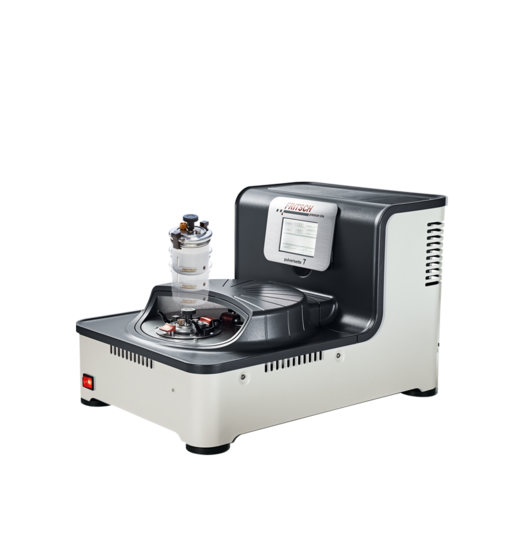

PULVERISETTE 1

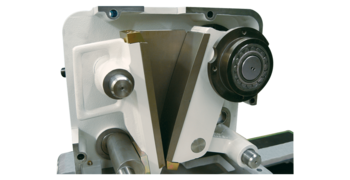

classic linePlease note: The crushing jaws and lateral support walls of the FRITSCH Jaw Crusher PULVERISETTE 1 classic line are available in 6 different materials in order to avoid undesired contamination due to material abrasion. The standard version is equipped with fixed and movable crushing jaws as well as lateral support walls made of hardened steel.

If required, we can equip your PULVERISETTE 1 classic line, model II, with fixed and movable crushing jaws in steel with a grooved surface, which have a different influence on particle shape and particle size distribution.

Normally, crushing jaws and support walls of the same material are used. Since the lateral support walls are subject to low stresses, however, the standard lateral support walls made of hardened steel can often be retained.

FIXED AND MOVABLE CRUSHING JAWS AND LATERAL SUPPORT WALLS

-

Material data for crushing jaws and support walls

Material Main component of the material Density g/cm³ Abrasion resistance Used for grinding material Hardened steel Fe – Cr 7.9 Good Brittle, hard samples Stainless steel Fe – Cr - Ni 8 Fairly good Medium-hard, brittle samples Chromium-free tool steel Fe 7.8 Good Medium-hard samples, RoHS samples Manganese steel Fe - Mn 7.9-8 Good Hard, brittle samples Hardmetal tungsten carbide WC 14.05 Very good Very hard, abrasive samples Zirconium oxide ZrO2 5.7 Good Medium-hard, brittle samples, metal-free grinding Aluminium Al 2.7 Fairly good Brittle samples

Normally, crushing jaws and support walls of the same material are used.

For the comminution of RoHS samples – such as for the XRF analysis – crushing jaws and support walls made of chromium-free steel are particularly well suited.

For completely iron-free pre-crushing of medium-hard brittle samples, for example in the ceramics industry, we can equip your FRITSCH Jaw Crusher PULVERISETTE 1 classic line with crushing jaws made of zirconium oxide, lateral support walls in zirconium oxide or aluminium, and with a special PVC funnel. So you will have absolute protection against iron contamination, such as for dental ceramics.

FIXED AND MOVABLE CRUSHING JAWS

for the comminution of brittle, very hard samples

General material specification:

Material: hardened steel - 1.2436

Abrasion resistance: good

suitable for: brittle, hard samples

Detailed information about the material you will find in the element analysis.

Crushing jaws made of hardened steel belong to the standard equipment of the FRITSCH Jaw Crushers and therefore they are included in the instrument price.

| General specifications | |

| Material | Hardened steel - 1.2379 |

| ISO/EN/DIN code | X153CrMoV12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 83.4 |

| Carbon – C | 1.55 – 2.10 |

| Molybdenum – M | ≤ 0.8 |

| Vanadium– V | ≤ 0.9 |

| Chromium – Cr | 12 |

| Tungsten– W | ≤ 0.8 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ |

| Hardness | 60 + 3 HRC |

Explanations on hardness data

for the comminution of brittle, hard samples

General material specification:

Material: hardened steel - 1.2436

Abrasion resistance: good

suitable for: brittle, hard samples

Detailed information about the material you will find in the element analysis.

Crushing jaws made of hardened steel belong to the standard equipment of the FRITSCH Jaw Crushers and therefore they are included in the instrument price.

| General specifications | |

| Material | Hardened steel - 1.2379 |

| ISO/EN/DIN code | X153CrMoV12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 83.4 |

| Carbon – C | 1.55 – 2.10 |

| Molybdenum – M | ≤ 0.8 |

| Vanadium– V | ≤ 0.9 |

| Chromium – Cr | 12 |

| Tungsten– W | ≤ 0.8 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ |

| Hardness | 60 + 3 HRC |

Explanations on hardness data

for the comminution of medium-hard, brittle samples

General material specification:

Material: stainless steel - 1.4571

Abrasion resistance: fairly good

Suitable for: medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Stainless steel – 1.4571 |

| ISO/EN/DIN code | X6CrNIMo Ti17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 63 |

| Carbon – C | max. 0.08 |

| Silicon – Si | max. 1.0 |

| Manganese – Mn | max. 2.0 |

| Phosphorus – P | max. 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 16.5 – 18.5 |

| Molybdenum – Mo | 2.00 – 2.50 |

| Nickel – Ni | 10.5 – 13.5 |

| Titan – Ti | 5 x C≤ 0.70 |

| Physical and mechanical properties | |

| Density | 8 g/cm³ |

| Hardness | 95 HB |

Explanations on hardness data

for the comminution of medium-hard, brittle samples

General material specification:

Material: stainless steel - 1.4571

Abrasion resistance: fairly good

Suitable for: medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Stainless steel – 1.4571 |

| ISO/EN/DIN code | X6CrNIMo Ti17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 63 |

| Carbon – C | max. 0.08 |

| Silicon – Si | max. 1.0 |

| Manganese – Mn | max. 2.0 |

| Phosphorus – P | max. 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 16.5 – 18.5 |

| Molybdenum – Mo | 2.00 – 2.50 |

| Nickel – Ni | 10.5 – 13.5 |

| Titan – Ti | 5 x C≤ 0.70 |

| Physical and mechanical properties | |

| Density | 8 g/cm³ |

| Hardness | 95 HB |

Explanations on hardness data

for the comminution of medium-hard samples

General material specifications:

Material: chromium-free tool steel – 1.1740

Abrasion resistance: good

Suitable for: medium-hard samples

Detailed information about the material you will find in the element analysis.

For the comminution of RoHS samples – such as for the XRF analysis – crushing jaws and support walls made of chromium-free tool steel are particularly well suited.

| General specifications | |

| Material | Chromium-free tool steel – 1.1740 |

| ISO/EN/DIN code | C60W |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 98.63 – 98.08 |

| Carbon – C | 0.55 – 0.65 |

| Silicon – Si | 0.15 – 0.4 |

| Manganese – Mn | 0.6 – 0.8 |

| Phosphorus – P | 0.035 |

| Sulphur – S | 0.035 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | 52 - 58 HRC |

Explanations on hardness data

for the comminution of medium-hard samples

General material specifications:

Material: chromium-free tool steel – 1.1740

Abrasion resistance: good

Suitable for: medium-hard samples

Detailed information about the material you will find in the element analysis.

For the comminution of RoHS samples – such as for the XRF analysis – crushing jaws and support walls made of chromium-free tool steel are particularly well suited.

| General specifications | |

| Material | Chromium-free tool steel – 1.1740 |

| ISO/EN/DIN code | C60W |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 98.63 – 98.08 |

| Carbon – C | 0.55 – 0.65 |

| Silicon – Si | 0.15 – 0.4 |

| Manganese – Mn | 0.6 – 0.8 |

| Phosphorus – P | 0.035 |

| Sulphur – S | 0.035 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | 52 - 58 HRC |

Explanations on hardness data

for the comminution of hard, brittle samples

General material specifications:

Material: manganese steel - 1.3401

Abrasion resistance: good

Suitable for: hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Manganese steel – 1.3401 |

| ISO/EN/DIN code | X120Mn12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 83.56 -85.96 |

| Chromium – Cr | < 1,50 |

| Silicon – Si | 0,3–0,5 |

| Manganese – Mn | 12,0–13.0 |

| Carbon – C | 1.1 -1.3 |

| Phosphorus – P | < 0.1 |

| Sulphur – S | < 0.04 |

| Physical and mechanical properties | |

| Density | 7.9–8 g/cm³ |

| Hardness | 27–32 HRC |

Explanations on hardness data

for the comminution of hard, brittle samples

General material specifications:

Material: manganese steel - 1.3401

Abrasion resistance: good

Suitable for: hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Manganese steel – 1.3401 |

| ISO/EN/DIN code | X120Mn12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 83.56 -85.96 |

| Chromium – Cr | < 1,50 |

| Silicon – Si | 0,3–0,5 |

| Manganese – Mn | 12,0–13.0 |

| Carbon – C | 1.1 -1.3 |

| Phosphorus – P | < 0.1 |

| Sulphur – S | < 0.04 |

| Physical and mechanical properties | |

| Density | 7.9–8 g/cm³ |

| Hardness | 27–32 HRC |

Explanations on hardness data

for the comminution of hard, abrasive samples

General material specifications:

Material: Hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: very hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 85.00 |

| Cobalt – Co | 15.00 |

| Physical and mechanical properties | |

| Density | 14.05 g/cm³ |

| Hardness | 1020 HV10 |

Explanations on hardness data

for the comminution of very hard, abrasive samples

General material specifications:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for very hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 85.00 |

| Cobalt – Co | 15.00 |

| Physical and mechanical properties | |

| Density | 14.05 g/cm³ |

| Hardness | 1020 HV10 |

Explanations on hardness data

for the comminution of medium-hard, brittle samples and metal-free crushing

General material specifications:

Material: zirconium oxide - ZrO2

Abrasion resistance: good

Suitable for: medium-hard, brittle samples, metal-free crushing

Detailed information about the material you will find in the element analysis.

Metal-free pre-crushing

For absolute protection against metal contamination, such as for dental ceramics. Crushing jaws made of zirconium oxide are perfect for completely metal-free pre-crushing of medium-hard brittle samples, for example in the ceramics industry, we can equip your FRITSCH Jaw Crusher PULVERISETTE 1 premium line and classic line with lateral support walls made of:

aluminium:

order no. 43.4040.13 – model premium line

order no. 43.3150.13 – model classic line

zirconium oxide:

order no. 43.4050.27 – model premium line

order no. 43.3160.27 – model classic line

polyamide:

order no. 43.4045.16 – model premium line

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

for the comminution of medium-hard, brittle samples and metal-free grinding

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: good

Suitable for: abrasive, medium-hard, brittle samples, metal-free crushing

Detailed information about the material you will find in the element analysis.

Metal-free pre-crushing

For absolute protection against metal contamination, such as for dental ceramics. Crushing jaws made of zirconium oxide are perfect for completely metal-free pre-crushing of medium-hard brittle samples, for example in the ceramics industry, we can equip your FRITSCH Jaw Crusher PULVERISETTE 1 premium line and classic line with lateral support walls made of:

aluminium:

order no. 43.4040.13 – model premium line

order no. 43.3150.13 – model classic line

zirconium oxide:

order no. 43.4050.27 – model premium line

order no. 43.3160.27 – model classic line

polyamide:

order no. 43.4045.16 – model premium line

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

LATERAL SUPPORT WALLS

Lateral support walls made of hardened tool steel belong to the standard equipment of the FRITSCH Jaw Crushers and therefore they are included in the instrument price.

General material specifications:

Material: hardened steel - 1.2436

Abrasion resistance: good

Suitable for: brittle, hard samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Hardened steel - 1.2379 |

| ISO/EN/DIN code | X153CrMoV12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 83.4 |

| Carbon – C | 1.55 – 2.10 |

| Molybdenum – M | ≤ 0.8 |

| Vanadium– V | ≤ 0.9 |

| Chromium – Cr | 12 |

| Tungsten– W | ≤ 0.8 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ |

| Hardness | 60 + 3 HRC |

Explanations on hardness data

General material specification:

Material: stainless steel - 1.4571

Abrasion resistance: fairly good

Suitable for: medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Stainless steel – 1.4571 |

| ISO/EN/DIN code | X6CrNIMo Ti17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 63 |

| Carbon – C | max. 0.08 |

| Silicon – Si | max. 1.0 |

| Manganese – Mn | max. 2.0 |

| Phosphorus – P | max. 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 16.5 – 18.5 |

| Molybdenum – Mo | 2.00 – 2.50 |

| Nickel – Ni | 10.5 – 13.5 |

| Titan – Ti | 5 x C≤ 0.70 |

| Physical and mechanical properties | |

| Density | 8 g/cm³ |

| Hardness | 95 HB |

Explanations on hardness data

General material specifications:

Material: chromium-free tool steel - 1.1740

Abrasion resistance: good

Suitable for: medium-hard samples

Detailed information about the material you will find in the element analysis.

For the comminution of RoHS samples – such as for the XRF analysis – crushing jaws and support walls made of chromium-free tool steel are particularly well suited.

| General specifications | |

| Material | Chromium-free tool steel – 1.1740 |

| ISO/EN/DIN code | C60W |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 98.63 – 98.08 |

| Carbon – C | 0.55 – 0.65 |

| Silicon – Si | 0.15 – 0.4 |

| Manganese – Mn | 0.6 – 0.8 |

| Phosphorus – P | 0.035 |

| Sulphur – S | 0.035 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | 52 - 58 HRC |

Explanations on hardness data

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: very hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 85.00 |

| Cobalt – Co | 15.00 |

| Physical and mechanical properties | |

| Density | 14.05 g/cm³ |

| Hardness | 1020 HV10 |

Explanations on hardness data

General material specifications:

Material: aluminium - 3.4365

Abrasion resistance: fairly good

Suitable for: medium-hard, brittle samples

Detailed information about the material you will find in the element analysis.

Metal-free pre-crushing

Crushing jaws made of zirconium oxide are perfect for completely metal-free pre-crushing of medium-hard brittle samples, for example in the ceramics industry, we can equip your FRITSCH Jaw Crusher PULVERISETTE 1 classic line with fixed crushing jaws (order no. 43.3100.27) or movable crushing jaws (order no. 43.3110.27) in zirconium oxide and with a special PVC funnel (order no. 01.7410.00). For absolute protection against metal contamination, such as for dental ceramics.

| General specifications | |

| Material | Aluminium AlZnMgCu1,5 |

| ISO/EN/DIN Code | 3.4365 |

| Chemical composition | |

| Element | Share % | Iron – Fe | 0.50 |

| Silicon – Si | 0.40 |

| Copper – Cu | 1.20 - 2.0 |

| Manganese – Mn | 0.30 |

| Magnesium – Mg | 2.1 - 2.9 |

| Chromium – Cr | 0.18 - 0.28 |

| Zinc – ZN | 5.1 - 6.1 |

| Titan – Ti | 0.20 |

| Physical and mechanical properties | |

| Density | 2,7 g/cm³ |

| Hardness | 2,75 Mohs |

Explanations on hardness data

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: good

Suitable for: medium-hard, brittle samples, metal-free crushing

Detailed information about the material you will find in the element analysis.

Metal-free pre-crushing

Crushing jaws made of zirconium oxide are perfect for completely metal-free pre-crushing of medium-hard brittle samples, for example in the ceramics industry, we can equip your FRITSCH Jaw Crusher PULVERISETTE 1 classic line with fixed crushing jaws (order no. 43.3100.27) or movable crushing jaws (order no. 43.3110.27) in zirconium oxide or aluminium lateral suport walls (order no. 43.3150.13), and with a special PVC funnel (order no. 01.5410.00). For absolute protection against metal contamination, such as for dental ceramics.

Lateral support walls of zirconium oxide are only suitable for crushing ceramic materials, minerals etc. and never for hard-tough samples such as metals.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

ACCESSORIES FOR METAL-FREE PRE-CRUSHING

Use the PVC funnel and the included clamping strips for metal-free pre-crushing of brittle samples. So you will have absolute protection against metal contamination for example for example in the ceramics industry – dental ceramics.

PVC FUNNEL INCL. CLAMPING STRIPS

Use the PVC funnel and the included clamping strips for metal-free pre-crushing of brittle samples. So you will have absolute protection against metal contamination for example for example in the ceramics industry – dental ceramics.

For this you will need additionally fixed and movable crushing jaws made of zirconium oxide* and lateral support walls made of zirconium oxide*.

fixed crushing jaw

zirconium oxide*- order no. - 43.3100.27

movable crushing jaw

zirconium oxide* - order no. - 43.3110.27

lateral support walls

zirconium oxide*- order no. - 43.3160.27

*Please note: Crushing jaws and lateral support walls made of zirconium oxide* are only suitable for crushing ceramic materials, minerals etc. and never for hard-tough samples such as metals.

DUST EXHAUST SYSTEM

An integrated connection makes it very simple to combine the instrument with a dust exhaust system for automatic removal of the fine dust arising during grinding. The dust exhaust system is also very useful when cleaning the grinding parts.

DUST EXHAUST SYSTEM

The exhaust system, dust category "M" according to DIN EN 60335-2-69 for 230 V/1~, 50/60 Hz, 1600 Watt is versatile:

For combination with the high performance and small volume cyclones.

To operate the FRITSCH Cyclones you need an exhaust system. The strong airflow ensures simple feeding, increases throughput, and reduces the thermal load of the samples. The high performance and small volume Cyclone separator can be combined with Universal Cutting Mills PULVERISETTE 19, the Variable Speed Rotor Mill PULVERISETTE 14 premium line and classic line. The small volume cyclone can also be combined with the Variable Speed Rotor Mill PULVERISETE 14 premium line and classic line even for passive utilisation – without sample exhaust.

The high-performance cyclone is ideal for combination with the Universal Cutting Mills PULVERISETTE 19 large, the Cross Beater Mill PULVERISETTE 16 and the Disk Mill PULVERISETTE 13 premium line for optimal sample extraction and for comminution of larger quantities.

For cooling of the Variable Speed Rotor Mill PULVERISETTE 14 premium line

By connecting the exhaust system with the connecting piece order no. 14.4214.00, the cooling of the mill can easily be enhanced.

For connecting to Disk Mill PULVERISETTE 13 premium line

The exhaust is simply connected to the PULVERISETTE 13 premium line and operated via a start and stop button on the instrument – for dust free comminution.

For connecting to the Jaw Crusher PULVERISETTE 1, Modell I + II classic line

Simply connect the exhaust system to the integrated connection of the PULVERISETTE 1. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For connecting to the Disk Mill PULVERISETTE 13 classic line

The exhaust system can be easily connected to the PULVERISETTE 13 classic line. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For exhaustion of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT

An exhaust system is necessary to ensure automatic sample exhaustion during dry measurement. When the measurement is completed it can also be easily used to manually clean the feeder.

Please note that the exhaust system article no. 43.9070.00, is not equipped with a fine filter and therefore dust may escape. Please consider the valid occupational health and safety regulations. This exhaust system is mostly recommended for dust-free grinding and the vacuuming of during the process developing fine dust in the upper part of the grinding chamber and for the cleaning of the grinding parts.

For vacuuming of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT, we recommended we recommend the exhaust system article no. 43.9060.00, which is equipped with a hose and an ultra-fine filter of dust class "H" according to DIN EN 60335-2-69, so that the escape of fine dust is reduced.

1 pack = 5 pieces

One pack is included in the scope of delivery of the exhaust system (article No. 43.9070.00).

These fleece filter bags should be used for the vacuuming off of fine, dry materials.

For the vacuuming off of coarse, wet materials are plastic bags available (article no. 43.9052.00).

1 pack = 5 pieces

One pack is included in the order of the exhaust system (article No. 43.9070.00).

These plastic bags should be used for the vacuuming off of coarse, wet materials.

For the vacuuming off of fine, dry materials are paper filter bags available (article no. 43.9055.00).

Accessories for combination of Jaw Crusher and Disk Mill

Mounting rack for combined use of the Jaw Crusher PULVERISETTE 1 classic line with the Disk Mill PULVERISETTE 13 classic line.

Accessories for combination

For fine pre-crushing of sample material with a feed size of up to 95 mm down to 0.1 mm final fineness in a single process and for continuous operation with the Jaw Crushers PULVERISETTE 1 classic line.

Fine pre-crushing from up to 95 mm down to 01 mm in a single process

A mounting rack with chute in combination with the Jaw Crusher PULVERISETTE 1 classic line (Model I + II) and the Disk Mill PULVERISETTE 13 classic line make it possible to grind up to 95 mm feed material down to a final fineness of 100 µm in a single process.

Continuous operation

With the use of the mounting rack and delivery chute, the Jaw Crusher PULVERISETTE 1 classic line (Model I + II) can be used for continuous operation. Conversion kit for the continuous operation of the Disk Mill PULVERISETTE 13 classic line on request.

Select the appropriate grinding parts and the desired configuration from the options available from our accessory pages for the:

Jaw Crusher PULVERISETTE 1, Model I classic line

Jaw Crusher PULVERISETTE 1, Model II classic line

Disk Mill PULVERISETTE 13 classic line

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation not included); for the independent utilization for the support of instrument qualification in the quality management system for the Jaw Crushers PULVERISETTE 1 classic line, Model I and II.

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Jaw Crushers PULVERISETTE 1 classic line, model I and II.